To answer this question, I am going to look at a little differently than other answers found on the internet. Beginner woodworkers need to identify materials that are not going to eat up what little budget they might have. They need to identify woods that are cheap but relatively stable. I truly believe that the one thing that holds me back – even today – is the fear of messing up an expensive piece of hardwood.

- Hardware Store

- Pallet Wood

- Department Store

- Neighborhood

- Thrift Store

- Construction Lumber

Many experts on the web steer beginners away from pine. However, when they talk about pine, they are referring to construction lumber that can be pine, spruce, or fur. Each of these species are available and will not break your bank. The downfall with using construction lumber is that it is usually not dried to a point where it is stable. This leads to twisting and warping as it sits in your shop drying. Even a few days can change the character of construction lumber.

So, here is my twist for this article. What if we could find pine that has been dried properly and that you could use without fear of devastating your household budget? Where do we look? My answers might surprise you.

Hardware Stores.

Yes, I said hardware stores. Look for already built items that contain laminated panel wood. I can pick up a 36” x 11.5” x 1” (91.44cm x 29.21cm x 2.54cm) pine stair tread at The Home Depot for $9.86USD. That is smooth, flat, and ready to use. This is laminated but for a beginner project, you could not touch any solid wood for that price. Especially if the project is to be painted.

For comparison, that is $3.43USD per board foot for a 1”(2.54cm) thick piece of clear pine.

Compare that to a piece of solid clear pine at the Home Depot and that will run you $24.18USD for a 96” x 8” x 1” (243.84cm x 20.32cm x2.54cm) board. Note that the actual board will be 96” x 7 ½” x ¾” (243.84 x 19.15cm x 1.90cm) bringing the comparative board foot price to $6.45USD per board foot

Another bargain found at the hardware store is laminated panel boards. These are glued up panels that are made from whatever was leftover in some factory somewhere. As I look at the Home Depot web site (and I imagine Lowes, Menards, Home Hardware, Masters Home Improvement, or Wickes (Thank you Wikipedia) will have similar items) I can buy a 1” x 20” x 48” (2.54cm x 50.8cm x 121.98cm) laminated “Panel Board” for $17.78USD. Comparatively, that is $2.67USD per board foot. No milling. No flattening. No planing. Great for CNC signs.

Pick up pallet wood

Watch for pallets that are being thrown out. Pallets are often made of hard and sturdy woods like oak. Even so, companies often feel that it is cheaper to buy new pallets than it is to ship empty ones back or repair broken ones to use again.

If you are reclaiming pallets, make sure that they are from the country you live in. Many times, pallets that are imported from other countries are fumigated and the sawdust particles could be harmful to your health. A stamp on the pallet may indicate that the shipment has crossed a boarder. If possible, trace the origin of the pallet when it has a stamp on it.

Another drawback with using pallets is the number of nails used to keep them together. These will all have to be removed.

Pallet wood will also give you a chance to hone your milling skills. The surfaces are not in any condition to build from. While this wood will have a low moisture content, it is not a given that it was milled square after the drying took place. As the pallets sit in a warehouse or are transported across the country, they are drying just for you. You will also find a lot of cracking in this wood.

Pallets can usually be picked up for free but be sure to ask before carting them off. Some places to look for used pallets include:

- Small businesses. They are less likely to mess with returning or repairing the pallet.

- Bottling companies. Especially soft drink packaging plants

- Construction sites. They would rather you take them than having to pay someone to.

- Supermarkets

- Department stores

- Behind strip mall

- Motorcycle dealerships

- 4 wheeler dealerships

Department Stores

I know, you think I am crazy for suggesting department stores. But look at some of the furniture they sell there. Yes, most is particle board – stay away from that. But occasionally, I see stools and folding tables there for less than $20USD that is made with the same laminated panels I discussed in a previous section. These finds are few and far between but when you find one, it is worth snatching it up for the wood. Be aware that even though it might say it is made from maple, it probably is not maple. But it is close enough not to worry about it,

This may not be as good of a deal as the other suggestions, but it is worth it to not have to mill or plane your stock before working with it.

Look around your neighborhood

Keep a sharp eye out around your neighborhood. Especially on trash day, there is a lot of good wood – of a variety of species – that is thrown to the curb. If you are shy about picking from the curb (I understand because I am) keep an eye open around the office for stuff they are replacing. Ask your friends what they are planning to do with furniture they are replacing.

If you are not into neighborhood trash, then keep an eye out for yard sales. Some families will put items up for sale before throwing them out. When I was a kid, I mistook “Garage Sale” for “Garbage Sale” – Just one little letter off but that is how I have always thought of them since. If it is not sold on Saturday, it is in the trash on Monday. Read the cautions I list in the Thrift Store section as they will also apply to yard sales.

Thrift Stores and Secondhand Stores

Awh… Thrift stores. Many treasures can be found at thrift stores. Any wood furniture you find at a thrift store is worth considering but consider the following as you look:

- Test everything that is painted for lead. Don’t take lead paint home with you.

- Look closely at the edges of any flat panel of the furniture. If you can detect a veneer glued to the surface, it will not work well for shop stock.

- If it is missing pieces, make sure the price is adjusted for it. Even though you are looking for that flat piece of hardwood, they do not need to know that.

- I would avoid anything upholstered. Just ripping of the upholstery to get to the wood you want can put particles in the air that who knows where it comes from.

- Old cribs and nursery furniture could be a value to you. These are things that most people avoid because they do not want to use them for their original purpose. Old Cribs and nursery furniture can be dangerous, but you are not going to use it for that – are you. Get a good price for these items. No one else is buying them.

- If you run across old construction material – Doors, Windows, or Molding – that are painted, use caution. The paint will most likely contain lead. I recommend passing on those items.

- Avoid anything that has a stink to it. I have bought furniture that stunk thinking that I could get it out or paint it in. You cannot. Leave it for someone else.

- Old tables can harvest a lot of project material. Look under the tabletop and make sure it is what it seems to be on the top.

Construction Lumber

Okay, construction lumber has its merits too. Not all of it is twisted and bent. If you spend some time looking through the pile, you will find some really good pieces.

For shop projects, you will want to find the Kiln Dried lumber. This will be lumber that has been stabilized and should not twist and shout on you any more. When possible, look for the sticks that contain the pith – or the center of the growth rings. This cut will not cup on you.

Other than that, look for straight grain patterns and tight growth rings. Cut around the twisted parts of the stick. You will most likely mill your pieces straight and flat before gluing them back together for your project.

For Reference:

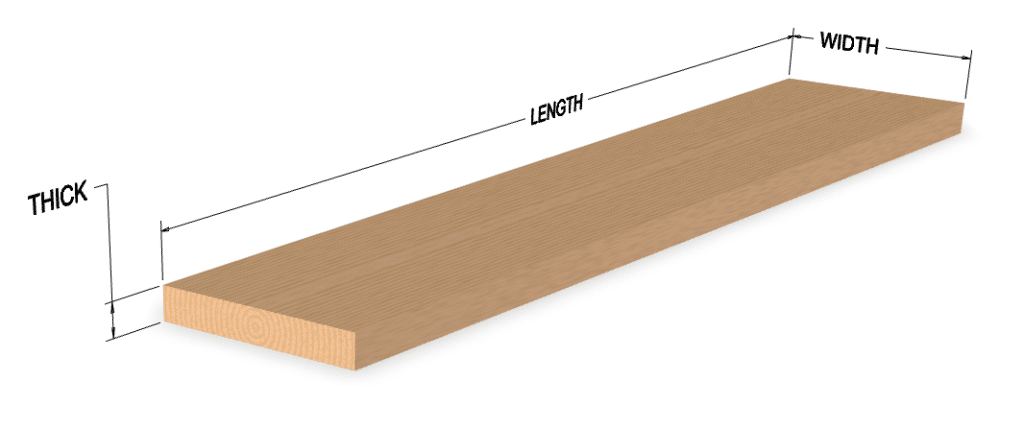

Boardfoot

A board foot is a volume calculation derived by multiplying Length in inches x Width in inches x thickness in inches / 144 (to convert inches3 to feet3). It is used to as a standard measurement to compare random sizes of wood with a common value. For example, a piece of wood 12″ x 12″ x1″ would be 1 board foot.

Nominal size vs actual size.

When wood is cut at the mill, it is cut to a nominal size – with specific dimensions. After the lumber goes through all of the processes at the mill, it ends up smaller than the nominal size. This is its actual size. Yet, you will be charged for the board feet of the lumber calculated on nominal size.

Here is a table of common lumber choices and their Actual sizes:

| NOMINAL SIZE | ACTUAL SIZE |

| 1″ X 4″ | ¾” X 3½ |

| 1″ X 6″ | ¾” X 5½ |

| 2″ X 2″ | 1½ X 1½ |

| 2″ X 4″ | 1½ X 3½ |

| 2″ X 6″ | 1½ X 5½ |

| 2″ X 8″ | 1½ X 7½ |

| 2″ X 10″ | 1½ X 9¼ |

| 4″ X 4″ | 3½ X 3½ |