If you have been reading my other articles in this series, you will know that I have identified 3 major types of straight edge router bits. They are Upcut, Down-cut, and Compression. This is the second in the series and will discuss what a down-cut router bit is.

A down-cut router bit is one of 3 basic shear cutting configurations found in common woodworking shops. A down-cut bit will leave a very clean edge on the top surface (the surface closest to the router) but may clog during a plunge cut. While down-cut router bits can be effective when used to trim laminate, they are also very effective on CNC routers when used properly.

The down-cut router bit has been around for a while but only recently has gained popularity in the CNC woodworking hobby world. On handheld routers, the down-cut bits have been used in conjunction with bushings or bearings to flush cut laminates for decades. The down-cut action would shear the laminate fibers (whether plastic or wood laminate) to produce a chip-free cut. Both the up-cut and the straight bit will pull against the laminate and cause chipping.

With the gaining popularity of CNC routers with hobbyists, the down-cut bit has additional benefits. The very action of shearing the material downwards tends to hold the workpiece to the table. This benefit is not without potential problems though. The downward shear action also will not clear the chips as efficiently as the up-cut or even the straight bit.

Down Cut Bits and CNC Router Tables

On a CNC, a down cut router bit will tend to push the workpiece into the table. This downward force helps to keep the workpiece from moving. Compare this to a handheld router where the base plate is directly attached to the motor and a down cut bit will push the workpiece away from the router.

Shearing Action

Down cut bits will push the wood away from the motor – no matter the orientation of the router. While table mounted, the motor is under the table, so the bit is cutting motion is actually “up” in relation to gravity. This will make it harder to stabilize the workpiece and introduce vibration, especially as the bit dulls.

Other Benefits of Spiral Router Bits

As with the other spiral bits, the spiral shape of the flutes will maintain constant contact with your workpiece and create a continuous slicing motion that tends to prevent chipping when cutting highly figured wood.

All flutes (Blades) will have constant contact with the material that you are cutting. As the blades go swirling into the material, they will produce a shearing action rather than a chopping action of the straight blade bit.

Plunge with Caution

Of the three types of spiral bit: Up-cut, Down-cut, and Compression, the down-cut is probably most used with a handheld router for trimming laminate. Since it can cut a with a shearing action that will not pull the laminate up away from the substrate, a very clean edge is maintained. It Is not recommended that a down cut bit be used with a handheld router to make deep narrow cuts.

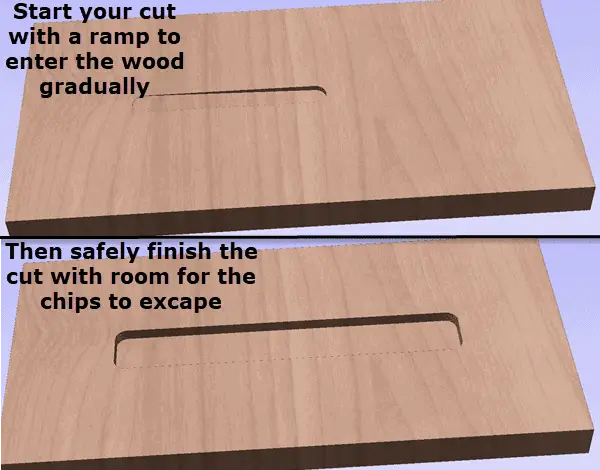

On a CNC, a down cut router bit can be used to create dados, grooves, rabbets, and other ploughs if programmed to do so correctly. Any time the chips are not allowed to escape, you will experience heat buildup and risk scorching your project. To avoid this on a CNC router, program a ramp action into the plunge and enter the wood gradually. This will provide an escape route for the chips as you start your cut.

Slicing Action

The spiral action of the down cut router bit will generate motion much like a screw. When the screw is held in place (bear with me on this one) and the workpiece is allowed to move, the screw will push or pull the workpiece in the direction of the threads. A spiral bit will do the same. Unlike a screw, it is desirable to strip the threads or – in other words – shear away the wood fibers. This shearing action is what creates a nice, sharp edge.

When using a down-cut bit, you should know that the edge of the workpiece that is closest to the motor will receive that nice, clean sharp edge while the edge away from the router will see some tear out and chipping.

The spiral shape of the flutes will also create a continuous slicing motion and tends to prevent chipping when cutting highly figured wood. With at least one cutting edge in contact with the workpiece, chatter and vibration are greatly reduced. At any one time, there should be contact by one or more flutes (Blades) as you are cutting. As the blades go swirling into the material, they will produce a shearing action rather than a chopping action created by the straight blade bit.

Plunge Better than Straight Bits

The flat end of a down-cut spiral bit is made to plunge straight into the wood and other softer materials. However, with the down-cut bits, this action should be avoided. Chip evacuation is a concern when you plunge straight into the workpiece. Burning and scorching will result from the heat buildup this causes. As described earlier, any plunging with a down-cut bit on a CNC router should be done by ramping the but into the workpiece gradually.

While this article has dealt mostly with flat bottom bits, everything covered here also applies to the other tip typed that comes with spiral cutting edges. Some of these choices are Ball Nose bits, Tapered Bits (creates a tapered side rather than a flat side), and Chip Breaker bits.

Because down cut router bits can tend to hold the workpiece to the CNC Router table, they are popular with the CNC router crowd. They can be used to rough out material quickly and to cut out the final profile of any work done on the CNC. These bits will leave a smooth edge that will require only a little sanding.

In conclusion, down cut router bits are very versatile and can be used in handheld routers, router tables, and CNC router machines. Down cut bits will compact the chips away from the motor and into the workpiece so special care must be taken to avoid heat buildup and scorching while machining.