If you are like me, you probably have a jar of leftover screws collecting dust in your shop. Like me, you don’t want to throw them away because that would be wasteful. And, still, like me, you realize that if you are not using them, it is also wasteful. I just was not sure how to tell the different sizes from one another. How do I determine the size of all those mechanical screws?

Thread size can be discovered in one of three ways:

1.) By using a Thread Gauge

2.) By measuring and calculating the thread

3.) Or by simply comparing the thread to a known thread size

For me, the most convenient way is to use a thread gauge. This works great for external threads – like on a bolt or screw – but the gauge can be rather tricky to measure inside of a nut.

For this reason, I often have to resort to using a combination of the above methods. I can find the thread size of a bolt rather easily using a thread gauge. Then I can use that bolt to find all of the nuts that fit it.

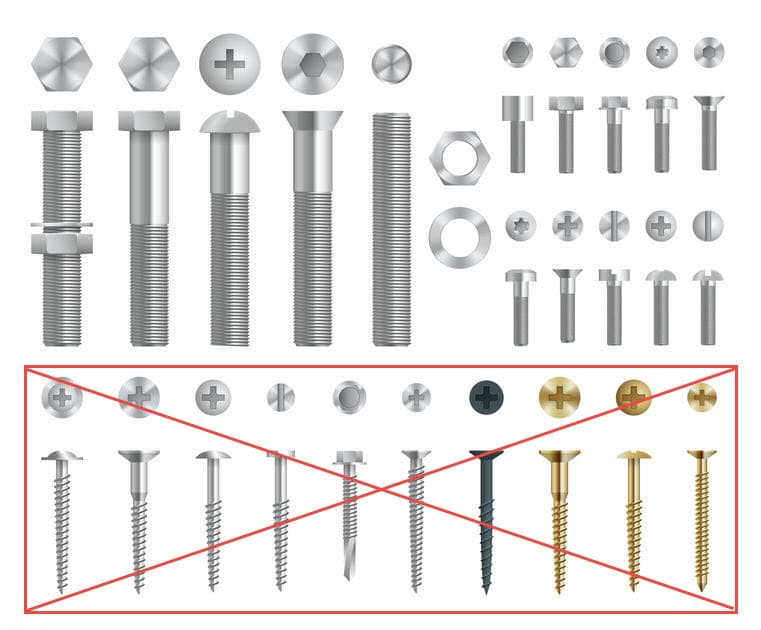

Let me start out by saying that I will be discussing only Machine Bolts and screws. The difference being that a bolt works in concert with a nut while the screw generally threads into a hole. I will also talk a little about self-threading screws near the end of the article.

What needs to be measured to find a machine bolt size

There are several standards used to define a threaded fastener in use around the world. I am focusing only on the UTS (Unified Thread Standard) standard mostly used in North America and the ISO (International Organization for Standardization) standard used worldwide.

Both of these standards use similar criteria to measure thread size. Both identify the thread major diameter, the thread pitch, and the length of the fastener. UTS actually used the measure of threads per inch (TPI) which is the inverse of the pitch.

Find the Thread Diameter

The thread diameter (called the major diameter) is simply the outside diameter of the thread. This is easily measured with a set of calipers. For metric thread, the diameter is expressed as M(diameter). M1 is 1mm in diameter, M6 is 6mm in diameter. It is plain and simple and there is no conversion required.

The UTS standard uses a #(something) for the smaller sizes and starting at a quarter-inch, switched to a fractional designation after the actual thread diameter.

Find the Pitch

Pitch is the distance from peak to peak on the thread where TPI is the number of threads (number of peaks) per inch. If you were to divide 1 by the TPI, you would have the pitch of the thread. I will make this conversion later in one of my charts to demonstrate just how similar the two thread standards are but why they are so dissimilar.

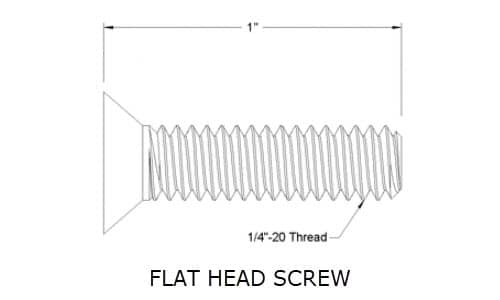

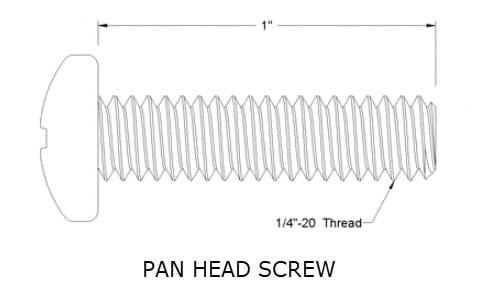

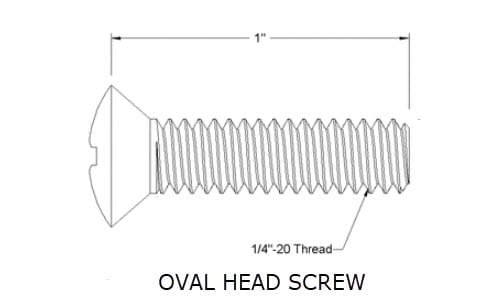

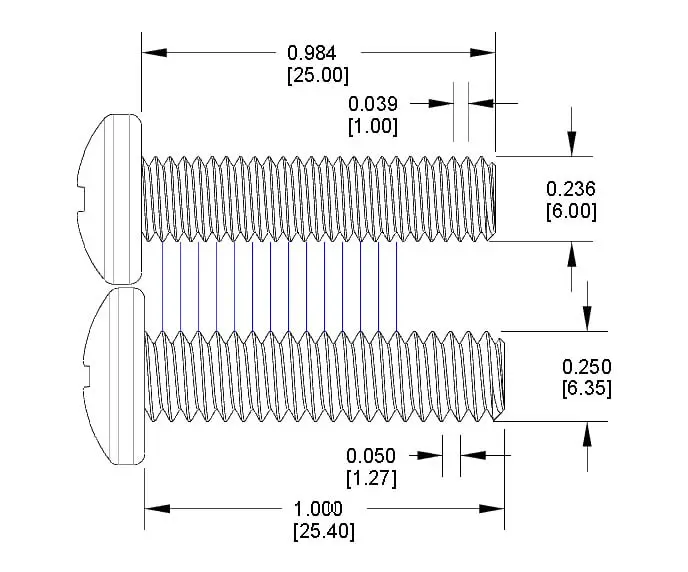

Find the Length

A third measure is the length of the screw or bolt. This is usually a measurement from underneath the head to the end of the bolt. The exception to this is any screw that is countersunk or a flat head screw. For these, the entire length of the screw is measured.

A Metric screw callout might look like this:

M6x1 x 8mm (6mm diameter, 1mm pitch, and 8mm long)

M10x1.5 x 15mm (10mm diameter, 1.5mm pitch, and 15mm long)

A Standard UTS screw callout might look like this:

#8x32x.5 (.164″ diameter, 32 TPI, and 0.5″ long)

1/4-20 x 1 (.25″ diameter, 20 TPI, and 1″ long)

The length of the screw or bolt depends on the type of fastener it is. Basically, the length is the distance from the surface of the piece being fastened to the end of the bolt. For example, a flat head bole will have none of the head exposed above the surface being fastened. A round head bolt will have the entire head exposed. This assumes there is no additional countersink or counterbore applied to the piece.

Diameter – Pitch Comparison Chart

Sample of diameter designations for both Metric and UTS sizes:

| UTS Name | Major Diameter (Inch) | MM Equivelent | ISO Name | Major Diameter (MM) | |

| #0 | 0.06 | 1.524 | M1 | 1 | |

| #1 | 0.073 | 1.8542 | M2 | 2 | |

| #2 | 0.086 | 2.1844 | M3 | 3 | |

| #3 | 0.099 | 2.5146 | M3.5 | 3.5 | |

| #4 | 0.112 | 2.8448 | M4 | 4 | |

| #5 | 0.125 | 3.175 | M4.5 | 4.5 | |

| #6 | 0.138 | 3.5052 | M5 | 5 | |

| #8 | 0.164 | 4.1656 | M6 | 6 | |

| #10 | 0.19 | 4.826 | M7 | 7 | |

| #12 | 0.216 | 5.4864 | M8 | 8 | |

| 1/4 | 0.25 | 6.35 | M9 | 9 | |

| 5/16 | 0.31 | 7.9375 | M10 | 10 | |

| 3/8 | 0.38 | 9.525 | M11 | 11 | |

| 7/16 | 0.06 | 1.5875 | M12 | 12 | |

| 1/2 | 0.50 | 12.7 | M14 | 14 | |

| 9/16 | 0.56 | 14.2875 | M16 | 16 | |

| 5/8 | 0.21 | 5.37718 | M18 | 18 | |

| 11/16 | 0.69 | 17.4625 | M20 | 20 | |

| 3/4 | 0.75 | 19.05 | M22 | 22 | |

| 13/16 | 0.81 | 20.6375 | M24 | 24 | |

| 7/8 | 0.88 | 22.225 | M27 | 27 | |

| 15/16 | 0.94 | 23.8125 | M30 | 30 | |

| 1 | 1.00 | 25.4 | M33 | 33 |

The Thread Gauge

The diameter and thread length are a simple measurement. I will touch on them in a later paragraph. For now, I will focus on the ways to find the thread pitch on a mechanical screw.

“Thread Gauge” is a rather ambiguous term. Any measuring tool that fits into the thread of a bolt can be considered a Thread Gauge. I have isolated 3 such tools that can be used to find the thread pitch on machine screws and bolts.

The first is a set of gauges that have a tooth profile machined into a thin piece of sheet metal. The tooth profile will fit perfectly into the thread pattern of a common machine bolt. This is my “go-to” tool when I have to find the pitch of a screw or bolt.

The idea behind these gauges to to fit the feeler gauge oger the teeth of the thread until a perfect match has been found.

The thread gauge has to fit perfectly over all threads in order to be a good match. If only 2 or 3 threads match before the gauge starts missing the mark, switch to a different feeler gauge and try again.

Measuring and Calculating the Thread

A second way to determine the thread size of a mechanical bolt is to simply measure. This can be tricky if you are not sure if you are measuring a metric bolt or a standard bolt. remember, the UTS threads are measured by threads per inch (TPI) while the Metric threads are measured between peaks.

Measuring between peaks can be very tricky on the small bolts. Some Metric screws can be as small as M0.24 with a pitch of 0.075mm. I’m not sure I have anything that can measure that small.

Comparing Your Screw to a Known Screw

This could be the fastest way to separate a few screws but can definitely take a lot of time to separate a whole jar full of screws. I will use this method mostly when I want to determine if 2 screws are metric. Or, if I am at the big box store and want to match the random screw that was one short of letting me put together some kit or furnature.

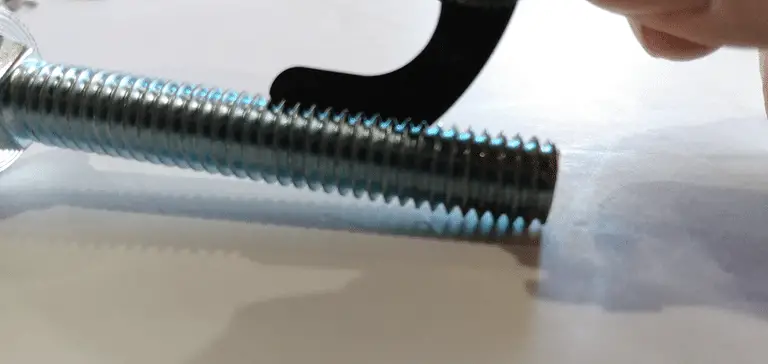

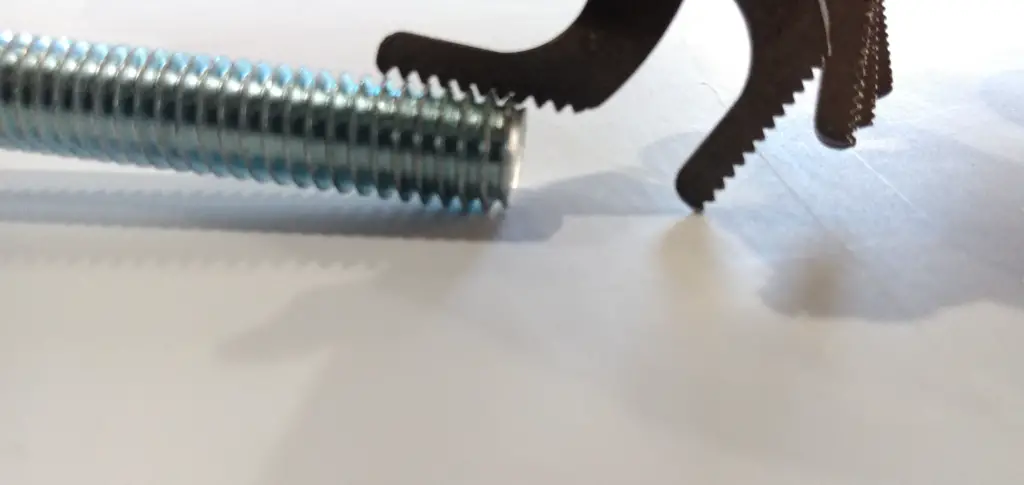

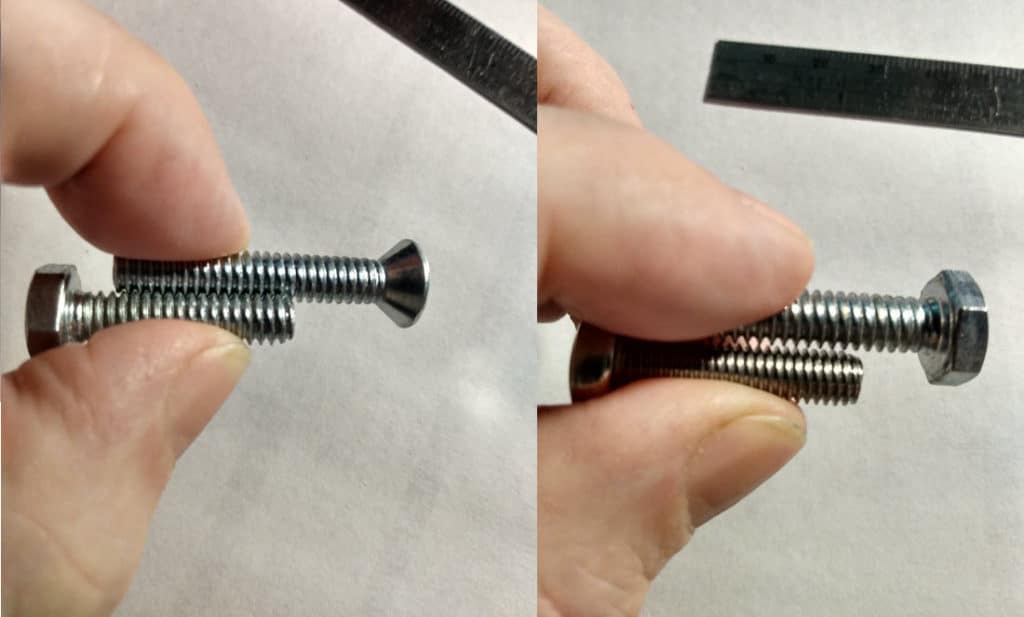

This method is a lot like using the thread feeler gauge. simply hold one bolt along side the other. Here I have tried to take some photos of an M6x1 bolt against a 1/4-20 bolt to show how – even though the diameter is similar size, the thread pitch is not.

If you are ever in a store that sells nuts and bolts, you may have seen one of these. They are very handy to help figure out what size bolt you are looking for.

Tools I have used

I find myself sorting through screws and bolts more at work than I do at home or in the shop. I have found these tools very helpful and some that I ordered to write this article.

If you would like to have your very own thread identifier stand at home, you might want to order one of these. To be fair, I did not order one of these for the article. It is just a little bit out of my price range right now.

Bolt and Nut Identifier Gauge

I must admit that I did not buy this tool to evaluate while writing this article. It was just a little on the pricy side. It does cover all of the bases listed above as you can determine the thread pitch (or TPI) for both nuts and bolts, and you can measure the length of the bolt. Check it from this link

Nut Bolt Screw Size & Thread Gauge

There are many versions of this design that you can buy. It has proven to be much more accurate and convenient than I expected. It will measure the major diameter of bolts and screws, the inside diameter of nuts and it has a thread pitch gauge that I thought would be junk but has turned out to be very useful. The tabs on each end measure both fine and coarse thread nuts and it is amazingly accurate. Unfortunately, the ones I have found will only measure a small range of UTS nuts. You can look into this tool from this link

Thread Pitch Feeler Gauge for Industrial Measurement

This has been my go-to for years. When I have to determine thread size for any reason, I can depend on my set of these thread gauges. Make sure that you get an accurate set and not just go for the cheapest set you can find. If you ever need to measure the small pitch screws, you will be glad you did. Follow this link.

Calipers Designed for Fasteners

I just want to hit one last tool. Calipers can get rather precise and sometimes that gets in the way. These calipers have a setting for measuring the Major diameter of screws and bolts as well as measuring hex nuts and hex heads on bolts and screws. It has been a real pleasure being able to get right to the size of the screw without having to nudge up and down to find a measurement that I was familiar with. Check out these Fastener-Cal Calipers