CNC (computer numerical control) routers are machines used for cutting various materials for manufacturing or creation. The usage of this technology has increased production for various companies resulting in more profits – but how much does this equipment cost to run per hour?

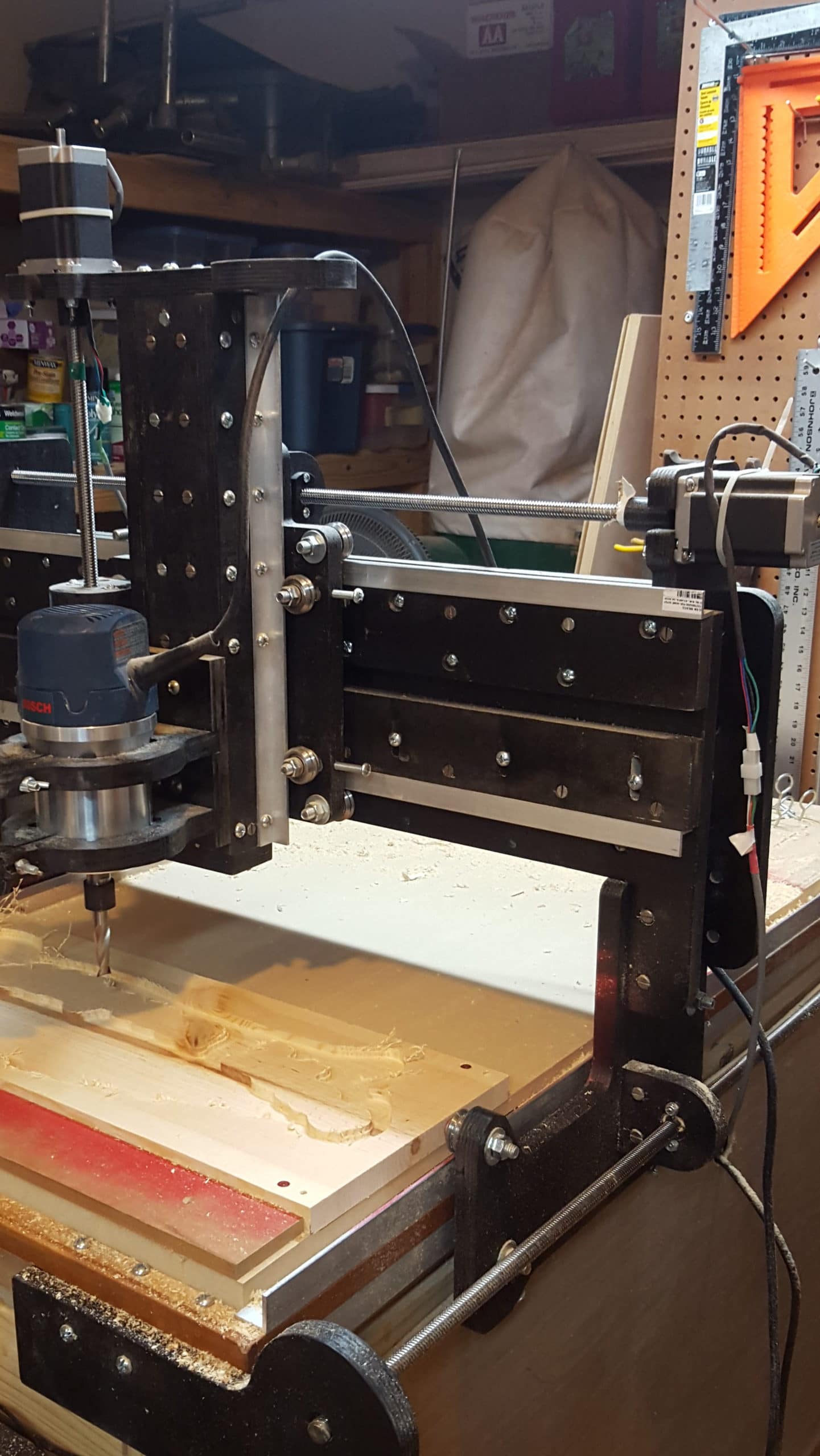

I use $0.28 (USD) per hour in electricity to operate my homebuilt CNC router operating at around 2¼ horsepower, with four 3 Amp stepper motors. Your cost may differ due to local electricity costs, power, size of the router or spindle, and the size and number of stepper motors.

In this article, we will be going over what goes into the cost of purchasing and running a CNC machine. If you would like to learn more, we encourage you to read on!

What Goes Into the Cost of a CNC Router?

Before we break down the cost of a CNC machine overall, we first have to know what a CNC machine does and how it works. CNC machining is often compared to 3D printing, but there is one key difference, CNC machining is a subtractive process, while 3D printing is an additive process. With CNC manufacturing, you are carving away material to create something new.

process, while 3D printing is an additive process. With CNC manufacturing, you are carving away material to create something new.

The advantages of using this technology are huge. It allows for precise, even cuts in a relatively short time frame, boosting product quality and production rates, which most manufacturers set out to achieve.

Your car, smartphone, and computer are all likely made with CNC. The technology can be used for small and delicate parts of large and heavy pieces. More examples of where CNC is used is as follows:

- Carpentry – Creating furniture, drawers, bookshelves, and other pieces of carpentry are very efficient with CNC. People can start small businesses

by manufacturing and selling their products with this technology.

by manufacturing and selling their products with this technology. - Auto Industry – CNC has proven to be exceptionally useful in the auto industry from the wheels’ creation to its engine.

- Aerospace – The production of aircraft has to be precise with absolutely no room for error. Thus a lot of the most important parts of a plane are created with the help of CNC, such as the wings, cockpit, and fuel system’s parts.

- Consumer Electronics – CNC is widely used in the electronics industry. For example, Apple Macbooks

are made by carving the aluminum to create the shell, keyboard holes, and even the thumb scoop. Other parts of electronics that are made using this technology are circuit boards and heat sinks.

are made by carving the aluminum to create the shell, keyboard holes, and even the thumb scoop. Other parts of electronics that are made using this technology are circuit boards and heat sinks. - Hobbyist –of course, I want to include the small shop and hobbyist in the examples. There are endless projects being done on CNC equipment by hobbyists. These CNC machines reach beyond the CNC router table and include laser etchers and cutters, Plasma Cutters, 3D Printers and, Drag Knives

.

.

How Do CNC Routers Work?

CNC routers fall under computer-aided machining or manufacturing computer-aided design (CAM/CAD ). This process involves designing a product, making a 3D model, and importing that model into a machine to manufacture it into a physical product.

). This process involves designing a product, making a 3D model, and importing that model into a machine to manufacture it into a physical product.

The CNC router itself is what carves out these models, and for it to do this, you have to tell it what to do using G-Code – a relatively simple computer language used for CNC programming.

– a relatively simple computer language used for CNC programming.

Not all CNC routers are made equal, however. These machines can range from affordable units made for engraving like this Gemmitsue 3018-PRO to high end $150,000 machines used in large plants for mass production.

to high end $150,000 machines used in large plants for mass production.

Since you are likely here for consumer-grade machines, we will spare you the little details on industrial-sized units, but it is worth noting that they are incredibly advanced and some of them are capable of operating on 5 axes .

.

A consumer-grade router is typically capable of vertical (x-axis), horizontal (y-axis), and depth (z-axis). These machines can handle drilling holes, cutting, and engraving flat objects. If you would like to learn about the full range axes for CNC machines in general, this video explains and shows this topic very well.

How Much Does a CNC Router Cost to Run?

If you are using a personal hobbyist CNC router by yourself, the cost per hour will be your electricity consumption. Assuming the machine is running at 1 kW/h, it would cost you approximately 12 cents per hour.

Now imagine if you decide to start a small business selling custom engraved wood. Let’s say you want to run the machine for 3 hours a day on average, the yearly cost for that would put you at $131.49 per year. If you are concerned about saving energy, this is something to keep in mind.

If you’d like to calculate how much your specific CNC machine costs to run, you can do it in these steps:

- Find the sum of the Router or Spindle amps plus the amps from each stepper motor and multiply by the line voltage in your country then divided by 1000. The result of this step is your kWh.

- KWH is then multiplied by the kWh cost in your area. The result is the cost to run the CNC Router per hour.

- You can include this number when calculating your shop rate or just have the number handy in case it comes up in conversation.

It’s important to note that those numbers are for low power CNC routers for hobbyist/entry-level usage . Machines like this are around $1000 – $5000, which is nowhere near as expensive as the ones a business might use.

. Machines like this are around $1000 – $5000, which is nowhere near as expensive as the ones a business might use.

CNC routers for production cost more money upfront ($150,000+) and electricity because they are far more powerful. For a machine that runs at 33kW, that cost could be as high as $4 per hour.

As you can see, you probably will never have to worry about extremely high energy consumption if you are buying a CNC router for personal use. But even if you do own a professional grade CNC router, you likely have a profitable, moderately-sized company mitigating these energy costs.

Don’t Forget Maintenance

It doesn’t end there however, maintenance is necessary for a CNC router. Wiping down the machine itself or using compressed air isn’t going to add much (if any) cost, but the cost of buying lubrication to keep the machine running smooth and changing filters will add up over time.

How much you’ll need to apply lubrication and change the filters depends on how often you are using your machine, but we recommend checking on things bi-weekly regardless, especially if you are consistently using your CNC machine.

How Does This Compare to Larger CNC Setup?

There are people who start out as hobbyists and overtime make a decent business out of it for themselves and eventually grow into heavier equipment. This results in a higher introductory and running cost.

Heavier duty CNC machines aren’t cheap to buy, but they aren’t too expensive to run. If you’ve made it to this scale, you are likely profiting enough to mitigate these costs. Let’s say you have a 6 horsepower machine and are paying 12 cents for each kWh; in this case, it is costing you 0.54 cents per hour.

Depending on how large your business is, the cost of running a CNC machine can mostly be the labor involved. Depending on the organization and machine, a CAM programmer needs to be hired to create the cutter paths and an operator to run the machine itself. Not only that, but we need to account for what the machine is being used for.

involved. Depending on the organization and machine, a CAM programmer needs to be hired to create the cutter paths and an operator to run the machine itself. Not only that, but we need to account for what the machine is being used for.

If you are in a heavy-duty environment working on large pieces, you may need an overhead crane to move those pieces around and/or special power feeds. You need to add all of these costs because they are required for the worksite to do its job.

to move those pieces around and/or special power feeds. You need to add all of these costs because they are required for the worksite to do its job.

Conclusion

The cost of running a CNC router varies a lot. The larger, more complex, and heavy the creation is, the more money it will cost due to the machines themselves and the labor involved.

If you want to place a machine in your garage and create furniture or engravings, you won’t have much to worry about since you are doing all of the work. The cost will come from buying the machine itself and materials. If you want to start a new hobby or try your hand at starting a business, it’s not bad to look into a CNC router!

Sources

- Openbuilds – CNC machines for the hobbyist

- Legacy Woodworking Machinery

- Mazak: What is 5-Axis Machining?

- 3DS: Introduction to CNC Machining – Subtractive Process

- Coupon Rich: 5 Ideas To Make Money With CNC Router

- APT-Mold: Know More About the CNCMachining Process For Macbook Pro Case

- Autodesk: CAD/CAM Software

- Wikipedia: G-code

- Manufacturing: CNC Machining Is More Accessible Than You May Think