CNC machines have become very popular in recent times due to the myriad of benefits the technology offers for both individuals and businesses. These include improvements in machining accuracy, boosts in production volume, and flexibility in manufacturing. However, since CNC machines can work with a router or a spindle, newcomers to the technology are always unsure about which one to go with.

A CNC spindle motor will be the best choice for many heavily used CNC machines. However, cost, complexity, and weight might prove to be factors for the hobbyist to choose the common woodworking router motor instead.

To be clear, both the motor from a handheld router and the more industrial router spindle motors are – technically – “spindles”. One definition of the word spindle is “Any of various mechanical parts that revolve or serve as axes for larger revolving parts…” (The Free Dictionary).

So, when I talk of a Router, I am speaking of the motor from an everyday handheld wood router that you can buy at a woodworking store. The router Spindle (or just spindle) will be referring to the VFD driven spindle motors.

The rest of the article will take a closer look at all the talking points you need to keep in mind when choosing between both options.

What Is a CNC Spindle?

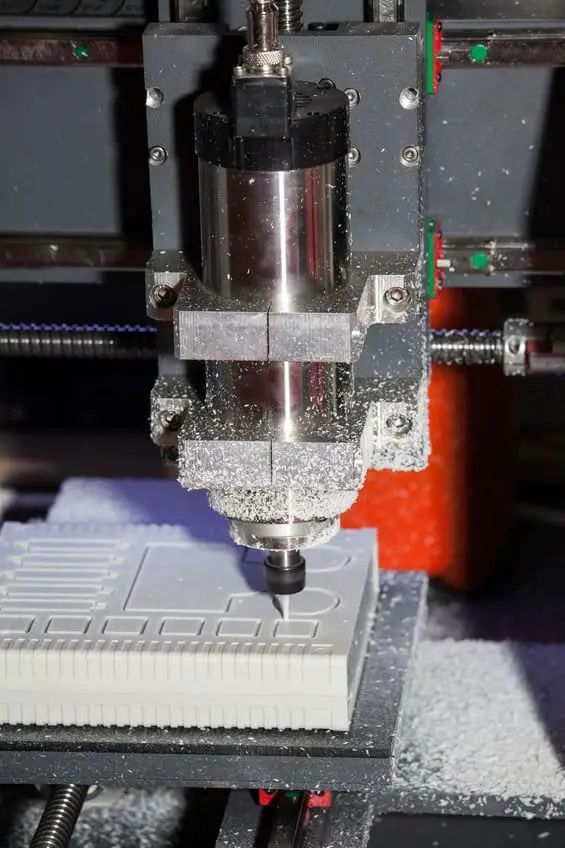

A spindle is a rotating assembly featuring a motor, a shaft, and a taper for holding tools. It rotates on an axis, and the CNC controller influences its movement. They are typically powered by electricity but can work with compressed air. There are three main types of CNC spindles:

- Self-contained spindle is the most popular due to the ease of installation. An example of this is the motor from a handheld wood router. With variable speeds of 10,000 to 30,000 RPM speed and 1½ to 3 HP, some variant of this router motor is what you’re most likely to find in most small and medium home workshops.

- Cartridge spindle is mostly found in industrial applications and in very enthusiastic CNC woodworking shops. It is made up of various components that can include the drive pulley, drawbar clamp, spindle taper, tool holder, etc. Each of these components plays a unique role in the spindle’s function.

- Fabricated spindle is another industrial option that is difficult to modify and rarely used by the average CNC business or hobbyist.

What is a CNC Router Machine?

A CNC router machine or CNC router table is a computer-controlled cutting machine designed to ensure more repeatable execution when working on wood, aluminum, steel, foam, and plastic. They have motors (spindles) that are controlled by computers to operate in 3 linear axes (and sometimes up to 3 rotary axes) . There are four types of CNC routers:

- Industrial CNC routers are very popular in the cabinet making industries today as they are very fast, repeatable, and flexible. These machines have many options available such as auto-loading, vacuum hold-downs, tool changers, and up to 5 axis operation.

- Mid-range CNC routers are like the industrial options, but they are smaller and lighter and usually do not have the accessories the industrial routers do such as vacuum hold-downs and

- Hobby CNC routers are a budget option designed for home use. Sometimes these hobby machines can rival the mid-range machines. Most hobbyists, however, utilize what is called a desktop router table.

- Specialty CNC routers cannot cut wood, but they are useful for engraving trophies, plaques, tags, etc.

CNC Router motor vs. Spindle: How Do They Measure Up?

To give you a better view of each side of the divide, we will look at CNC router motors and spindles under the metrics covered below:

Ease of Use

A spindle is best for advanced or professional users who have a perfect understanding of how to use one to complete specific tasks. The spindle motor is designed to run long periods of time without overheating or breaking down. However, setting up a spindle can take some doing. The complexity begins right from when you must plug it in, as it requires a 3 phase inverter/driver.

A router, on the other hand, can be used by just about anyone. Just plug it in and flip the switch (following all safety protocols so you don’t get hurt). Therefore, it is preferred by hobbyists and is regarded as an excellent tool for getting started with CNC. Using one does not require any extensive engineering knowledge as it is basically plugged and play. You just need to find an outlet and get started.

Power Ratings

A spindle is generally better equipped for high-power usage compared to a router. It is rated as an industrial device, using an international standard root mean square (RMS) power. You can be sure it will continuously hit the advertised power.

With a router, the power rating advertised is typically a “peak” horsepower. This means that the manufacturers can use the highest burst of horsepower achievable for the router, even if it was sustained for a few seconds. This leads to a tool that will never quite be as powerful as a spindle.

Lifespan and Durability

If you do a lot of heavy-duty CNC work, or just use your machine frequently, you’ll get better value for money using a spindle, as routers tend to wear out more frequently when they’re put under a similar level of strain.

A spindle can last up to 12,000 hours, depending on the load it must deal with over its lifespan. Under the same conditions, a router will almost certainly break down before it hits 1200 hours. So, a router user doing the exact same work with a spindle user will most likely replace their router multiple times before the CNC spindle owner.

Router motors are almost always a brush type motor. When the brushes wear out, they can be replaced. It is advisable to replace the bearings as required also.

The spindle motor is a brushless motor that uses changing frequency from a VFD to spin the armature. This tends to increase the lifespan and reduce maintenance cycles on these motors. The bearings will still wear just as in the router motor.

Noise Levels

A spindle drives with a high frequency – no brushes. This makes it a lot quieter when working compared to a router. If you’re cutting, however, both of them will be noisy. Therefore, you should always protect your ears, whether you are working with a spindle or a router.

Cooling

A spindle is often water-cooled but smaller motors can be air-cooled. The water cooled systems will require a dedicated setup incorporating a reservoir, piping, pump, and, in some cases, a cooling circuit. With a router, you will not need such a setup as they are air-cooled.

Speed Control Accuracy

Spindles run with VFDs, which makes controlling the RPM and Speed more accurate than routers and ensures virtual speed control. Routers do not provide any feedback. This may be okay in most use cases, but in others, you’ll need to control the RPM directly on the router motor and the speed (how fast the cutter is cutting through the material) manually or from the program.

Variable speed – the ability to adjust the RPM of the motor – isn’t a necessity with routers, but it is important if you have the intention of working with larger diameter bits in the future. It’s important for safety purposes and also to ensure you’re getting the smoothest cuts in all projects.

Cost

A router is a relatively inexpensive item that you can find any time online or at your woodworking store. They can be easily replaced, hence why virtually all the sellers offer some sort of warranty on them. A spindle, on the other hand, typically costs up to ten times more than a router.

If you are under a fixed budget, it may look like a great decision to go with a router. However, you need to be sure that a router represents proper value for you over an extended period.

Which Should You Go For?

To decide on whether to go for a spindle or a router, you should go over each of the points above and make a note of how each of the points relates to your specific situation. For example, if you are a hobbyist and don’t know how to put together the electrical setup needed to power a spindle, choosing a router looks like a better decision. The same applies if you can’t set up a water-cooling system for a spindle.

However, the real metric to use in your decision-making should be the scope of your CNC business. If the bulk of your earnings come from other sources, you can follow your budget and choose the option that works for you. If you are running a serious CNC business full-time with many customers trusting you for higher cut quality, you should go with a spindle instead.

If you want the lowest cycle times, the longest bit life, and the best cut quality, you need faster feed rates and lower RPM than a router can typically cope with. This is especially true when you are working with veneer plywood, hardwood, aluminum, and plastics. So, if you’re still in the hobbyist camp, a router can work. Otherwise, you should invest in a spindle.

Conclusion

Spindles and routers have their unique benefits in the CNC machining world. However, they also have downsides. The best one to go for will always vary from one person to another, but you should consider your workload and your typical project lineup to make the best decision.

For regular power-intensive CNC work, a spindle will typically provide more value for money than a router.

Sources

- Hand Tools for Fun: CNC Spindle vs. Router

- Build Your CNC: Spindle vs. router

- Open Builds: What is the difference between spindle and router?

- Reddit: Router vs. Spindle?

- CNC Zone: Industry Arena

- CAM Heads: Spindle vs. Router

- Reddit: I’m buying a router. Is variable speed a must-have? Can I do without a plunge base?

- CNCNutz.com