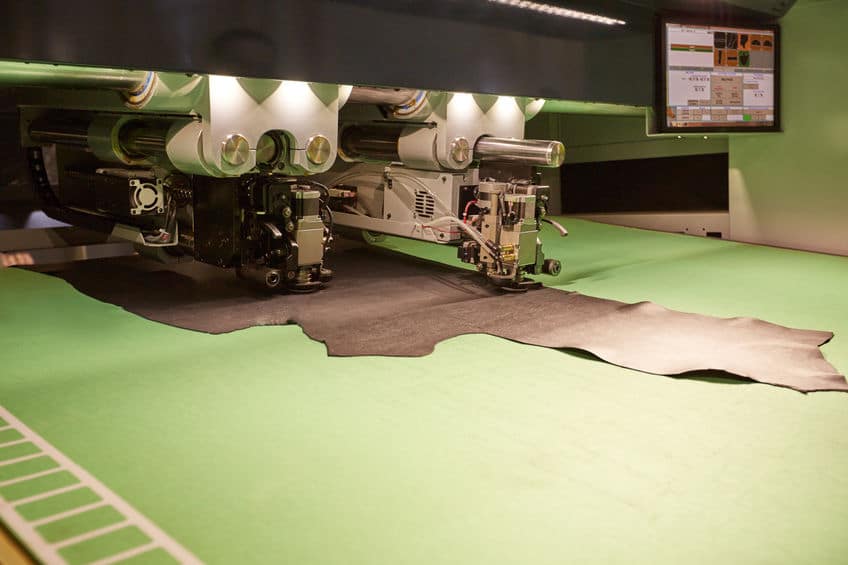

Leather is a difficult material to cut without the right tools. Computer Numerical Control is a handy tool with a variety of applications from engraving, to cutting materials, to 3D printing and much more. However, they are not without their limits, and leather cutting was one such limitation for a while.

A CNC router can cut leather, but there are lots of important factors to consider and to ensure your cut is done correctly. Certain equipment, such as specific bits or blades are required. There is also a right and wrong way to secure the leather to the table with a CNC router.

If you’re interested in using a CNC router to cut leather, then stick around. This article has all the insider info on what you’ll need to do to ensure the best cuts when using a CNC router to cut leather. Keep reading for more.

Can I use a Regular Router Bit to Cut Leather?

By “regular router bit”, I assume you mean a metal rod with sharp knife edges milled into it spinning at 12,000 RPM or more. The short answer is “yes, but not recommended“. A spinning bit making contact with soft, stringy-grained material is not ideal. Let me explain.

For CNC routers, there is no one regular bit. Instead, there are a variety of bits, and some are used more commonly than others. Of course, depending on what material you are working with or what type of jobs you are doing, you will have different styles of bits.

However, there are some router bits that are more common such as:

- Straight bits: As the name suggests, this bit cuts straight edges in your material.

- Spiral bits: The knife edges spiral down the length of the bit creating a shearing action for the cut. These can shear either upward or downward. See my articles What is a Down-Cut Bit

and What is an Up-Cut Bit

and What is an Up-Cut Bit for further explanation of spiral bits.

for further explanation of spiral bits. - Edge forming bits: These come in a variety of profiles that yield different edge types.

- Individual application bits: These can be used to make grooves or other specific applications. There is a multitude of these for whatever you may need.

Along with these types, there are a variety of materials that bits are made out of as well. However, if we consider these more common bits, for most of them, it will be impossible to cut leather or will result in harmful cuts.

Searching online will show that there are exceptions to this, though. Some people have had success using tiny bits of 1/32 inches while using tape to hold the leather down. This brings us to the main issue with trying to cut leather: How to securely hold leather while cutting. I’ll talk about that a little later.

However, when cutting leather, a spinning router blade can be problematic. Leather does not shear cleanly and regular shear cutting router bits may grab the leather and bind. Let’s talk about some alternatives.

Alternatives to Regular Router Bits

Instead of using regular rotating router bits, there are options better suited for cutting leather. Laser cutter add-ons are popular alternatives. The installation process for these vary in difficulty, but there are easily found tutorials for whichever laser cutter add-on you decide to use.

The appeal of a laser cutter is that they work very quickly with leather and very cleanly since they are not making physical contact with the leather. The main thing to keep in mind if you decide on a laser cutter is that the fumes released by the burning leather will smell terrible and that you will need eye protection if you plan on watching it cut.

Both of these problems are easily solved through proper eye protection and with a method of removing fumes.

The other common alternative for cutting leather is cutting a bit. These tend to yield clean cuts and overall excellent results. It is still recommended that you find a way to keep the leather weighed down, however, for more consistent results.

There are a variety of styles for cutter bits, but the one that seems to yield the best results with leather is the drag knife style.

Possible Challenges of Cutting Leather with a CNC Router

The main issue that arises when cutting leather is that the leather moves quickly. The way most router bits work is by spinning rapidly, allowing the cutting edges to move the removed material up the flute of the bit.

The flute is the cutting edge and spiral gap in the bit. For harder materials, this works out fine, but for textiles such as leather, this poses a problem. The rapid rotations of your selected router bit move the leather around while cutting.

This means that the edge you are cutting will be rough or stringy. For thicker pieces of leather, this issue is mitigated slightly, but for thinner pieces, it is particularly problematic.

Additionally, the leather can also sometimes get caught up in the rotating router bit. This results in a problem not only for your leather project but also for your bit and your whole router.

Some people have found ways to counteract this by using very small bits and finding ways to keep the leather from moving.

Here are some of the successful methods:

- Placing the leather on a semi-porous material and using a downdraft table

- Making custom cut acrylic templates to weigh down the leather

- Using adhesives to adhere the leather to a material

However, even with these fixes, there are issues such as leaving residue or requiring additional materials.

What is a Drag Knife?

A drag knife is a cutter bit that looks like a razor blade attached to a metal housing at an angle. The CNC machine drags that knife along the surface of your material and cuts into it cleanly.

There is a variety of manufacturers of drag knives, but the most common is the Donek Tools drag Knife. While they are pricier than standard router bits, it is recommended over a spinning router bit by many people for leatherwork and offers a margin of safety over regular router bits.

It is important to note with all bits, including this specific one, that there are different sized collets for routers. Make sure that whichever cutter bit or router bit you purchase will fit your routers collect, or that you have an adapter.

| It is important to mention that the router will not actually be powered on when using a drag knife. The drag knife only requires a pivot point provided by the free-spinning router shaft and does not spin like a regular router bit. Edit your G-Code or simply disconnect the power to the motor any time you use a drag knife. |

How Thick can the Leather be?

The thickness of leather that can be cut will vary depending on what type of bit you are using. If you decide to use a regular smaller router bit, it will also depend on your specific machines RPM. For laser cutters, unfortunately, it will be a matter of trial and error as well.

It is recommended that you begin your testing with cheaper materials before moving on to your actual project. Additionally, doing research and finding which laser cutter will serve your specific needs best will help you out in the long run.

For cutter tools, it will depend on the size of your blade and which cutter you are using. Most, if not all, cutters can have their blades replaced, so you should be able to find one that fits your needs.

Additionally, some cutters will even accept Exacto knife blades. This means you can get pretty deep cuts. Keep in mind, however, that this is also dependent on the power of your CNC router machine.

However, if you decide to use the Donek Tools drag knife, their website has specifications on the different models they offer. The D1 and D3 models are best suited for thinner materials from 0.010 in up to 0.0625 in, or 1/16”.

The D2 and D4 models are best suited for thicker materials from 0.010 into 0.250 in, or ¼”. They offer their models in sizes to fit ½” and ¼” collets.

Helpful Hints

There are a lot of options for how to cut leather with CNC without getting frayed ends or ruining your machine. However, if, for some reason, you cannot get access to the necessary tools, there are other options.

There is, of course, the option of cutting by hand, but this is not ideal for most projects. Luckily, there is a multitude of websites out there that offer CNC leather cutting services.

Keep in mind, though, that many websites will require a bulk order, so make sure the specific website you choose can order the amount you need. This company, Ponoko, offers laser cutting leather services with same-day shipping and the ability to order what you need.

Final Cut

So… can you cut leather with a CNC router? The short answer is yes, you sure can. However, it’s essential to make sure you have the proper tools and the correct technique to ensure you’re going to get the best possible results.